| Power Conveyor - Index

|

Horizontal - Belt Conveyors

|

Series #MSB

Medium Duty

Slider Bed - Belt Conveyor

|

Series #HSB

Heavy Duty

Slider Bed - Belt Conveyor

|

Series #MTSB

Medium Duty - Trough

Slider Bed - Belt Conveyor

|

Series #HRB

Heavy Duty

Roller Bed - Belt Conveyor

|

Horizontal - Accumulating - Roller Conveyors

|

Series #10MPA

Light Duty

Belt Driven - Minimum Pressure

Accumulating - Roller Conveyor

|

Series #20MPA

Medium Duty

Belt Driven - Minimum Pressure

Accumulating - Roller Conveyor

|

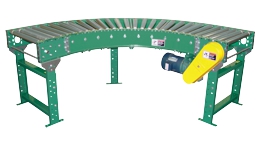

90 Degree - Roller Curves

|

Series #10BDC

Light Duty

V-Belt Driven

90 Degree - Roller Curve

|

Series #20BDC

Medium Duty

V-Belt Driven

90 Degree - Roller Curve

|

Floor to Floor - Incline - Belt Conveyors

|

Series #HSF

Heavy Duty - Slider Bed

Floor to Floor - Belt Conveyor

|

Series #HRF

Heavy Duty - Roller Bed

Floor to Floor - Belt Conveyor

|

Power conveyors are for transporting product and can be used in a variety of applications including packing, inspecting, sorting, assembly, manufacturing and testing to name a few. DC Graves offers a variety of power conveyors that can ship in 5 business days after receipt of order. This "quick-ship" option ensures that anyone can have a power conveyor system up and running in your facility in only a few weeks. Among the power conveyors available in the quick ship option are horizontal belt conveyors, trough slider bed conveyors, roller bed belt conveyors, accumulating power roller conveyor, powered roller curves, and inclined floor to floor power conveyor.

Horizontal Power Belt Conveyor: One important feature of power belt conveyor is it is very forgiving (compared to power roller conveyor) in terms of product characteristics and product sizes it can transport. With roller conveyor the product must have a rigid and flat bottom and must have a minimum of three rollers underneath it at all times. You could not put a canvas sack of widgets on a roller conveyor but a belt conveyor would handle it no problem. This unique advantage to powered belt conveyor allows for the transportation of various products, packages, etc...However, horizontal power belt conveyor does have some drawbacks as well. In order for the conveyor to operate efficiently, there must be a way for your product to leave the end of the belt. The belt will continue to drive the product that has nowhere to go at the end creating product a traffic jam. You can either have products fall off the end of the conveyor to a bulk bin, provide an operator (human or robotic) to pick packages at the end of the line, or transfer the packages to gravity conveyor or other transport system.

Horizontal Accumulating Power Roller Conveyor: As opposed to belt conveyor, your product is conveyed using either 1.375" or 1.9" diameter rollers that are driven by a PVC drive belt. In order for the powered roller conveyor to work correctly, your product must be long enough to be on 3 rollers at all times and have a flat, rigid bottom. The belt driven live roller conveyor will accumulate packages at the end of the line eliminating the need to keep the end of the conveyor clear from incoming packages or positioned with an operator to remove packages. Accumulating power roller conveyor is also available in curves.

Floor to Floor Inclined Power Conveyor: As the name infers, these powered belt conveyors are designed to move products from one floor to the next either on a mezzanine or any other viable structure. Available in two models, one with a slider belt and a heavy duty model with rollers under the belt. When equipped with proper controls and motors the conveyor can be configured to operate in both directions, facilitating transportation up or down the conveyor.

|